Eurobrick - Technical Guide : Expansion Joints

We are frequently asked technical questions about the installation of our systems. One topic that comes up quite often is expansion or movement joints; what are they, why are they necessary, how and when should they be used? Here, we will look at expansion joints in a bit more detail.

We are frequently asked technical questions about the installation of our systems. One topic that comes up quite often is expansion or movement joints; what are they, why are they necessary, how and when should they be used? Here, we will look at expansion joints in a bit more detail.

It is important that the expansion joints are constructed in accordance with the system’s installation instructions, so that any differential movement of structures, settlement and shrinkage of timber frames or expansion and contraction of the slips and systems which can exert damaging pressure on the brick slip cladding system is avoided.

Joints can be completely filled with mastic, however Eurobrick supply a 20mm thick compressible polyethylene joint filler rod, which takes up most of the depth and this is then finished with polysulphide mastic or similar non aggressive sealant.

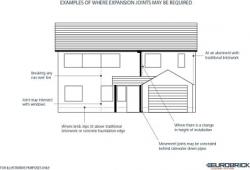

Movement joints are required at intervals not exceeding 6m, measured vertically or horizontally, of uninterrupted brickwork. Joints comprise a complete break in slips and system backer panel of about 15mm width. Movement joints, vertical and horizontal, can intersect with or spring from window or door openings and be concealed behind rainwater downpipes where it is practical and convenient to do so.

System panels must be fully fixed in accordance with our Installation Guide with lines of fixings on both sides of movement joints.

It is also important that movement joints included in the substrate structure should be carried through to the front of the brick slips cladding system.

Movement joints MUST be constructed at abutments with other materials. A good example is where a run of brick slips meets traditional masonry at an abutment. The brick slips tend to be carried by the frame of the building while the traditional brickwork is ground bearing. Differential movement can be foreseen at such locations and should be mitigated by inclusion of a movement joint.

Where brick slip cladding is installed above traditional brick or block, or a concrete foundation slab or similar, if the substrate is at all prone to movement a horizontal joint will be required. Failure to construct a joint in this location may result in shrinkage of the frame putting damaging pressure on the brick slips and panels and system failure may ensue.

Cladding to timber frame structures may require joints at every floor level to allow for frame shrinkage and settlement. The extent of shrinkage which can be anticipated depends on a few factors including whether or not roof, dry-lining or floor materials are already installed. The best source of information on this subject will be the project engineer or the timber frame supplier.

Our technical staff are available to answer any queries you may have about our systems, including any further questions on expansion or movement joints. Please call 0117 971 7117 or email info@eurobrick.co.uk