PENDOCK

Suppliers of: Pipe Boxing, Column Casings, Boiler Pipe Casings, Washroom Cubicles, Vanity Units, Low Surface Temperature Radiator Guards

Pendock are the UK market leader in the manufacture and supply of a comprehensive range of pipe boxing, column casings, encasement products and washroom cubicles. Pendock offers Architects, Design Engineers and Installers the perfect pipe boxing and general cover solutions via a range of both standard and bespoke products which are offered in a range of materials, colours and finishes.

PRODUCTS:

Pipe Boxing and Boiler Pipe Casing

Pendock Profile provides the perfect hiding place for building services. Our preformed plywood casings provide a versatile and practical solution for concealing unsightly pipework, electrical cabling such as beams and cills. We provide a wide range of both 5mm and 8mm casings with a 90 degree angle for use at skirting or corner locations together with a range of 5mm preformed plywood casings with 115 degree angled return for use at dado or midwall level or encasing cables or pipes up to 50mm diameter.

Our range of Boiler Pipe Casings are a practical and simple solution to hiding and protecting pipework above and below the boiler providing easy acess for maintenance and servicing.

Pendock Profiles also offer bespoke casing and boxing in aluminium which can also be manufactured with hatches for easy access.

Column Casings

Pendocks range of column casing produce a unique and perfect finish and for interior high usage areas also offer a range of bump rails and wall protection.

Pendock HVAC perimeter casings are increasingly popular for specifiers. They have a space saving design which incorporates smooth curves with a choice of grilles to maintain heating and cooling efficiency.

Washroom Cubicles

Pendock has become a major force in the Washroom market combining design flair and technial expertise. Our wide range includes easy fix solutions for single and multiple cubicle installation in corners, islands or between walls and are inexpensive.

Pendock Robuste compact laminate cubicles provide high durability and design flexibility to meet most demands whilst our Matrixe range is not only functional and attractive but easy to clean and virtually maintenance free and is an adaptive pre-plumbed solution for both commercial and public sectors.

Pendock vanity units include style, simplicity, uncomplicated design and easy installation and our pre-plumbed sanitaryware, brassware and accessories have been selected for best functionality and style.

Radiator Guards - LST

Pendock for many years have been the leader in Low Surface Temperature (LST) protection for schools, nurseries, hospitals, care homes and GP surgeries. The Safe-Heat range is easy to clean, feature an anti-bacterial coating as standard and follow NHS guidelines.

Pendock Safe Heat guards are available with Easi-Clean access panels mounted at the front allowing full access to the inside of the guard without the need to remove it completely from the wall.

Floor Ducting

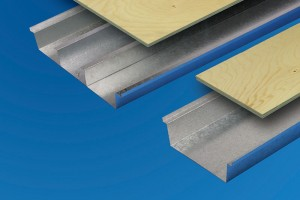

Pendock floor ducting is a two-part system comprising a pre-formed tray, produced from 22 gauge hot dipped galvanised mild steel (to BS 2989: 1982 class Z2) and a 12mm plywood cover (to BS 1203: 1979). Return flanges give recessed support to the pre-cut plywood covers, laid flush with the rest of the finished floor.

Bespoke Pipe Boxing, Ducting, Casing and Cubicle Projects

Whilst Pendock offers an extensive choice of ‘off the shelf’ products throughout the various ranges of products we manufacture, we also have the ability to design and manufacture bespoke pipe boxing, floor ducting, column casings and washroom cubicles.

A Nationwide team of Project Managers are available to visit either an architect or designers office or meet on site to offer advice on what can be manufactured to suit specific design requirements.

Further technical information, image galleries and product specifications are available through the Pendock website or via the BPi Download Library.

Pendock casings – aesthetic, practical and versatile

Over the past 30 years, the Pendock name has become a byword for decorative architectural casings, with countless projects using its ‘Radius’ column casings and ‘Linea’ building linings ranges to conceal structural components and building services, while also improving aesthetics.

Over the past 30 years, the Pendock name has become a byword for decorative architectural casings, with countless projects using its ‘Radius’ column casings and ‘Linea’ building linings ranges to conceal structural components and building services, while also improving aesthetics.

The company is also well known for washroom systems and pre-formed services casings, as well as low surface temperature (LST) radiator guards and floor ducting products.

Although all Pendock products are relevant to architects, specifiers and contractors, the most commonly specified are those within its ‘Radius’, ‘Linea’ and ‘Washroom’ ranges.

Radius column casings

Designed to conceal interior and exterior structural steelwork, as well as concrete columns, Pendock Radius unites the company’s six individual column casing types.

The pre-formed plywood range is for interior use only and is available as circular or square profile casings, as well as extended circles or rectangular shapes. Although they are available unfinished for on-site painting, most are specified pre-finished with high pressure laminates (HPL) or with real wood veneers.

GRG casings are also for interior use only and are regularly specified as circles. However, as they are produced from moulds, GRG casings can also be manufactured to bespoke shapes and dimensions to meet the needs of specific projects.

Pendock’s GRP casings are also produced from moulds, enabling them to be bespoke manufactured to individual project specifications, but they can be used for both interior and exterior applications. Their durability and weather resistance also makes them well suited for high traffic areas, such as public buildings and retail.

The versatile metal column casing range is also designed for interior and exterior projects. Manufactured from aluminium or stainless-steel, they are weather resistant, highly durable and can be specified in a wide range of shapes and finishes.

In addition to a wide palette of RAL, BS or Pantone colour PPC finishes, anodised, brushed, polished and textured finishes, including Rimex, are also available, depending on the material specified.

Linea building linings

The extensive Pendock Linea building linings range comprises nine different architectural finishing products, including exterior rooflights, parapets and soffits, alongside interior pilasters, perimeter casings and ceiling features.

The Linea range allows architects to specify several lining elements within a project from a single source, as opposed to these items being unlisted or ‘floating’ within various sections of a specification document.

By using this approach, a high degree of consistency to be achieved across different aspects of a project, as the elements can be manufactured, supplied and installed, if required, from a single specialist manufacturer. This helps reduce risk, mitigate potential co-ordination issues on site and allows a uniform, high-quality finish to be achieved.

Washroom cubicles and systems

Pendock’s cubicle and washrooms range includes five systems – Classic, Classic Plus, Robust, Ultimate and Education – as well as modular IP panels and bespoke solutions.

The Classic range is manufactured from 18mm thick MFC (melamine faced chipboard) and is designed for use where economy and simplicity are key factors, while the Classic Plus uses the same core, but is faced with high pressure laminate. Both models are edged with 2mm PVC.

The Robust and Ultimate cubicle ranges are produced from 12mm compact laminate (CL) and are designed for high traffic and wet areas, including high humidity zones while the dedicated Education range covers washrooms from nursery through to further education and is available in 18mm MFC or HPL, as well as 12mm CL.

For complete design versatility, every aspect the IP panel system and bespoke washroom range can be specified, including the core material, finish colours, graphics, panels and door sizes, as well as pilasters and ironmongery. Vanity units, back panels and accessories are also available alongside DDA and Approved Document M compliant solutions.

Award winning motorway services – Pendock’s inside story

Following the completion and opening of the award-winning Skelton Lakes motorway services near Leeds, Architecture Today spoke to our Technical Project Manager, Gavin Byram, to explore the design & specification process and how the principal technical challenges were overcome.

Following the completion and opening of the award-winning Skelton Lakes motorway services near Leeds, Architecture Today spoke to our Technical Project Manager, Gavin Byram, to explore the design & specification process and how the principal technical challenges were overcome.

Project overview:

Designed by Corstorphine & Wright Architects, Leeds Skelton Lake Services is located at Junction 45 on the M1 and sited within a 40,000-square-metre country park. The environmentally sensitive project employs a series of large undulating green roofs supported by exposed glulam beams, while generous double-height spaces and clerestory glazing provide high levels of daylighting and a welcoming interior.

A series of bespoke architectural linings from the Pendock Linea range, formed key elements of the interior design and fit-out by combining practicality, aesthetics and durability in a busy environment with high levels of pedestrian traffic.

AT: What was the brief and how was the design developed?

GB: The brief from main contractor Morgan Sindall, was to supply bulkhead linings at first floor level and pilaster linings on the ground floor. The former is designed to conceal the steel floor structure on the upper level, while the latter provides an attractive and decorative finish to the open shop fronts.

For the bulkhead linings, the concept was to mimic the shape of the steel floor beams, which follow a gentle curve. This was favoured for both aesthetic and practical reasons, as it provided a convenient and clearly defined space for shop signage within the vertical ‘web’. It was decided to manufacture the bulkheads in moulded GRP, so that the lightweight linings could accurately and smoothly follow the changing line of the steel floor structure.

Added to this, the material’s pliability meant that it would be more forgiving when it came to fixing on site and adapting to reasonable construction tolerances. If a GRG-based lining was chosen, it would be prone to cracking in this type of application. The bulkhead itself comes from our Pendock’s Linea range and is part of the standard GRP offering.

However, the design and finish are bespoke to the project, which is typical of the way we work. It is worth pointing out that we can also manufacture linings from the Linea range from plywood, MDF, compact laminate, HPL, stainless steel and aluminium, as well as textured metals.

The bespoke pilaster linings are also included within our Linea range. Here, GRG was specified for reasons of fire safety, material compatibility with the drylined walls above, and ease of finishing and painting. The material also allows us to manufacture products from moulds and it is this capability that enabled us to incorporate 30mm radiused corners into the design, which ensures that there are no sharp edges around the shop fronts.

A recessed, 1mm thick stainless steel kickplate is bonded to the base of each pilaster for added protection and durability. While it was not a requirement on this project, we can design and produce Linea pilaster casings to accommodate additional services, such as mains sockets, fire alarms and CCTV.

AT: What were the main technical challenges and how were these resolved?

GB: The bulkheads were perhaps more challenging than usual due to the concave radius design of the shop fronts. The only way that we could accurately manufacture the linings was to template the bulkhead on site.

This involved taking thin sheets of hardboard and overlaying them on the steelwork. The timber was then cut to the line of steel beams, before being taken back to the factory and used to form the curved moulds for GRP linings.

In the case of the pilaster linings, we carefully measured each shop front on site before manufacture. The demise line that runs across the retail frontage usually ensures greater consistency. However, we still checked for construction anomalies on the sides of the columns and changes in floor-to-ceiling heights caused by multiple shopfitters working across different stores. This allowed us to maintain the level of accuracy required to ensure the final installation went smoothly.

One of our USPs, you could say, is that we rely on our own detailed surveys as a means of producing bespoke solutions. This ensures that our products accurately fit the dimensions and shapes present on site, rather than what is shown on the drawings. For example, we often find rainwater pipes and other services, which don’t appear on drawings, packed around columns as a means of solving unforeseen problems.

Following the survey, we prepared detailed drawings prior to manufacture. Every pilaster and bulkhead casing was numbered and marked up on plan drawing, making onsite installation clear and straight forward.

AT: What fixing methods were used onsite and how did Pendock ensure accuracy and quality?

GB: The decorative nature of the linings meant that the client wanted to see neat, clean lines with no visible fixings. As a result, the bulkhead linings are primarily bonded to the timber subframe.

Mechanical fixings are also used, but these are concealed by the store signage panels. The pilaster linings are mechanically fixed into a timber subframe and the counter-sunk screwheads are filled, sanded, refilled then given three coats of paint along with the rest of the item to achieve a smooth and consistent finish.

Once we had completed the installation, the bulkhead linings and pilasters were wrapped with thick corrugated plastic sheets to protect them from accidental damage during final site clear up.