SWISH BUILDING PRODUCTS

Suppliers of: PVCu cladding fascia soffit boards PVC weatherboard plastic bargeboards PVC rainwater goods, PVCu Fascia

Swish Building Products is one of the UK’s leading manufacturers of low-maintenance cellular PVC building products, including fascia, bargeboards, internal and external cladding.

These low-maintenance building products are well accepted within the public sector, with both Local Authorities and Housing Associations, and within the private sector for domestic, commercial and new-build applications.

Swish Roofline

The Swish Roofline range offers the specifier a fully integrated fascia, soffit and bargeboard system with a wide range of components in white, foiled and coloured finishes for new build and replacement projects.

Swish cladding

Swish cladding is a weatherproof rain screen layer that can help to improve the thermal performance of a property when installed in combination with insulation. There is a choice of Shiplap, Open V, Tee Gee and Featheredge designs available in four sizes.

Swish offers a 20 year guarantee on its white cellular PVC profiles which also carry BBA and BSI certification. The popular foiled and coloured boards carry a 10 Year Guarantee as does the Swish Rainwater system.

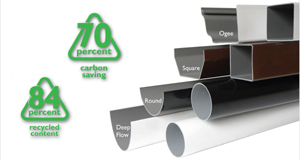

Swish rainwater system

The Swish rainwater system is ideal for those who wish to specify quality products that have a reduced carbon footprint as it is manufactured from 84% recycled PVC material.

All Swish guttering systems and colours are Kitemarked and are offered in a range of:

- Round Gutter

- Deep Gutter

- Ogee Gutter

- Square Gutter

Since being awarded ISO 14001 in 2007 Swish has concentrated on reducing the carbon footprint of its manufacturing and distribution facilities and is now one of the most efficient and environmentally responsible plastics manufacturers in the industry. Swish has consistently reduced its CO² output, water consumption and waste generation during this period. In 2014 Swish was awarded ISO 50001 Energy Management Certification which it holds alongside Responsible Sourcing of Construction Products –BES 6001 and the Occupational Health and Safety OHSAS 18001 Certifications.

Gallows Brackets & Dentils

A range of Gallows and Dentils for roofline, canopies, bay and oriel windows. The dentils may be secretly fixed and the gallows brackets are load bearing and capable of offering structural support to door and window canopies.

PVC Trims

A wide range of trims that provide a neat, clean and dry means of finishing or making good the areas around windows and doors. They eliminate the need for wet trades, thereby reducing installation times to a minimum. Many may also be used as decorative additions in roofline and cladding installations.

PVC Window Boards

Window boards and trims provide a neat, clean and dry means of finishing or making good the areas around window and door reveals. They eliminate the need for wet trades, thereby reducing installation times to a minimum.

you can also visit our social media pages on Facebook and Twitter

Further technical information, image galleries and product specifications are available through the Swish Building Products website or via the BPi Download Library.

Swish Building Products - Covid 19 update 19th July 2021

Covid 19 update 19th July 2021

Covid 19 update 19th July 2021

Following the latest COVID 19 update regarding the easing of Government restrictions, Epwin Group will continue to operate with current on-site safety measures in place for the foreseeable future.

Our main priority is to ensure the health and safety of our employees as well as those of our customers and suppliers during the continuing pandemic in order to best support our customers and maintain the wider industry supply chain.

We encourage all colleagues, customers and suppliers to fully observe all of our recommended on-site safe operating procedures, in particular, the appropriate wearing of masks, suitable social distancing and regular hand washing. We also encourage everyone to take sensible steps outside of work to keep themselves and their work colleagues as safe as possible.

If you have any queries please contact us: 01827 317200 or email info@swishbp.co.uk

Swish Building Products - Taking sustainability on the road

As an environmentally conscious company, Swish Building Products knows that its responsibility to sustainability goes beyond its manufacturing processes. Ensuring our environmental credentials extend past our production facility is the responsibility of Richard Lacey, Transport Manager with Swish Building Products:

As an environmentally conscious company, Swish Building Products knows that its responsibility to sustainability goes beyond its manufacturing processes. Ensuring our environmental credentials extend past our production facility is the responsibility of Richard Lacey, Transport Manager with Swish Building Products:

"Over the past 13 years, Swish has developed robust, sustainable and achievable environmental goals with regards to the development and manufacture of its products. However, it also understands that these objectives need to be sustained throughout all its business processes, and that includes the distribution and transportation of its end product."

Over the past few years Richard and his team have been tasked with examining the Swish distribution chain - from the vehicles used and driver conduct, to the planning of delivery routes - to ensure they are always operating as sustainably as possible. The team's first consideration was our fleet of delivery trucks, as Richard explains:

"As part of the European Union we adhered to the Euro Vehicle Rating, which measures vehicle emissions. The more advanced Euro Rating you have, the higher fuel efficiency the vehicle is likely to have. For example, it takes five Euro 6 Rated trucks to produce the same amount of NOx as just one Euro 5 Rated truck, and it takes three Euro 6 Rated trucks to produce the same particulate matter as just one Euro 5 Rated truck.

"We have been using Euro 6 Rated trucks for several years now and despite no longer being part of the European Union, we continue to use this rating system to ensure we are operating the most environmentally sound fleet of vehicles we can.

"The way these trucks are driven is also just as important as their emissions when it comes to reducing our carbon footprint. This is why we've invested in a comprehensive state-of-the-art route planning system."

The route planning system allows drivers to see entire routes on screen, which enables them to plan the most efficient route possible. Having the ability to see all scheduled deliveries also means trucks can be loaded more effectively, making the most of a single journey and ensuring customers do not receive goods via multiple deliveries. Working in conjunction with the route planning system, we will also be introducing a tracking system which will monitor the actions of the individual driver rather than the vehicle.

Richard explains how the system will work: "The new tracking system will examine the actions of a vehicle's driver, from their braking and cornering to their speed, which will enable us to assess if an individual is driving economically. By monitoring this, we will be able to educate our drivers on best practice driving skills with regards to being more environmentally aware. We have also capped the maximum speed of our trucks to 56mph, despite high sided vehicles being able to travel at up to 60mph, which is not only helping to reduce fuel use but also keeping our drivers – and those around them – safer."

We have continued our commitment to sustainability within our supply chain with the recent purchase of eight new 18t rigid vehicles which will be delivered this September. These trucks are to replace our existing fleet and with the most up-to-date engine technology are more economical – and safer – than their predecessors.

"Sustainability is at the heart of every Swish business operation, and we are constantly looking at ways we can improve our processes with sustainability in mind," concludes Richard. "This latest investment in our fleet is just one example of our commitment to ensuring we are doing all we can to minimise our impact on the environment."