COMPONENT DEVELOPMENTS

Suppliers of: Stainless Steel Drainage Channels Stainless Steel Floor gullies Stainless Steel drains trench drains

Component Developments (CD) is a market leader in the design, manufacture and supply of stainless steel building products to the construction industry.

The CD product range includes internal and external drainage channels, gullies, various types of surface protection and also manhole covers. These products are especially suited to the leisure, food & beverage production, catering and healthcare industries.

Due to the make-up of stainless steel our products offer unique benefits for designers, specifiers and contractors across the board. The ease of cleaning ability makes stainless steel the first choice for hygiene conditions, such as restaurants, hospitals, kitchens, shower areas and other places where people congregate. Stainless steel has a proven record of success in the area where sanitation and ease of cleaning are so important.

Sales Support and Technical Advice

Manned by a team of experienced engineers, our state of the art facilities located in Telford, Shropshire, houses our design, engineering, technical sales, production and logistics departments all in one place. This allows us the freedom to create high quality products in a very short lead time, while offering a friendly and reliable service.

You Design It, We Fulfil It

We offer a comprehensive design service to help you achieve exactly what you need for the project. Equipped with the latest design software, we will produce a detailed CAD layout made to your specific requirements.

We understand that timing is of the essence and having your product made quickly and delivered to site at a time that is most appropriate to you is something we take very seriously.

Dedicated Specification Site: www.specifystainless.co.uk - Manufacturing and delivering outstanding hygienic Drainage Systems to the built environment.

Dedicated Online Store: shopstainless.co.uk - Online store for standard components, parts and spares.

CD Stainless Steel Drainage Channels & Trench Drains

CD offers a comprehensive range of stainless steel drainage channels to suit any application and floor finish, combined with the ability to produce bespoke systems. Including:

- Standard Drainage Channel (3000 Series) - With a minimum channel depth of 50mm, these are ideal for use where a high volume of direct discharge waste from process equipment into the floor is required.

- Super Compact Channel (3600 Series) - Conical shaped with no gratings, this drain is easy to maintain. This economical drainage channel fits flush to the floor and requires a 50mm depth.

- Modular Drainage Channel (6000 Series) - Has a shallow channel depth of 40mm and is strictly restricted to 155mm overall width. The 6000 Series is suitable only for tiled, concrete or resin floors.

CD Stainless Steel Gullies & Floor Drains

Our range of floor gullies includes trapped outlet gullies with a range of gratings. Ideally for use in many wash down applications including catering kitchens, abattoirs, dairies and food processing plants.

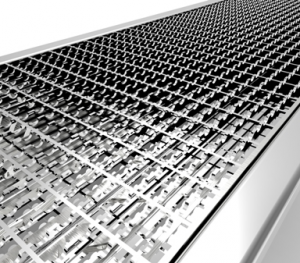

CD Stainless Steel Gratings & Grids

We supply both mesh and perforated floor gratings for use with our channel drainage systems. Anti-slip, smooth and heel safe options are available.

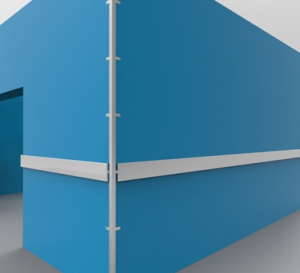

CD Stainless Steel Wall Guards & Wall Protection

For the protection of walls, we manufacture a range of buffer rails and corner guards and skirtings in austenitic stainless steel to suit a wide range of wall finishes including tiles, fair-face block work and p.v.c sheeting.

CD Kerbs

Further to our surface protection range we supply stainless steel kerbs, which are ideal for use in Food processing factories with resin flooring. We offer three types:

- Single Sided Kerbs (8100 series) - These are mainly used around the perimeter area to sit alongside the exterior wall and are then infilled with C30 concrete (or similar) making them very strong and impact resistant. Walling is then built on top.

- Double Sided Kerbs (8200 series) - For sectioning an area into different rooms, the double sided kerbs are ideal. These can cross path using internal and external corner pieces and stop ends.

- Retro Fit Kerbs (8300 series) - For pre-existing walls in refurb situations, retro fit kerbs offer the solution. Also ideal for use in conjunction with the single and double kerbs as a continuation of the protection in cold areas and against block walls.

Barrier rails / Bollards / Crash Protection

All bollards and barriers can be either surface mounted or core drilled. All offering Ideal protection from forklift trucks, pallet trucks and passing trolleys.

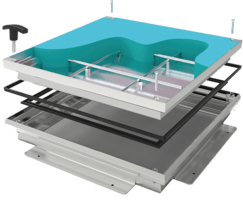

CD Stainless Steel Recessed Manhole Covers

The covers allow easy access below floor level and are designed with a recessed top to sit resin, tiles or screed flush with the floor. Standard sizes available ex-stock. Heavy duty range also available for trafficked areas to support forklift and pallet trucks.

Component Developments External Drainage Concord College

Concord College is a co-educational international boarding school for children between the ages of 13 to 19. It has a reputation for impressive grades, and even more impressing facilities. Component Developments’ were approached to help design, manufacture and supply the stainless steel drainage to the exterior of the new science block.

Concord College is a co-educational international boarding school for children between the ages of 13 to 19. It has a reputation for impressive grades, and even more impressing facilities. Component Developments’ were approached to help design, manufacture and supply the stainless steel drainage to the exterior of the new science block.

This project was the architect’s final job before he retired, and his tools of choice were a pencil and paper. This meant that Component Development’s had to draw up his designs on AutoCad to ensure the dimensions, and radius of the channels would be exact.

The final design agreed was for curved slot drains and drainage channels that had the same radius as the curve of the building above. Due to the curve in the slot drain, Component Developments had to include multiple discrete access points within the slot drain, which could be infilled and hidden with the floor finish, whilst still allowing access to the system if required.

From drawing approval it took 3 weeks to manufacture and despatch to site as per the request of our client.

The final solution was a sustainable, impressive drainage solution which mirrored the architect’s vision and bought it to life.

Component Developments Supply University of Birmingham Floor Drainage

The University of Birmingham (UoB) has an average total student population of 35,000 making it the fourth largest university in the UK. The University of Birmingham has consistently been ranked in the top four of the British Universities & Colleges Sport (BUCS) league table and was the first UK University to offer a sports degree in 1954.

The University of Birmingham (UoB) has an average total student population of 35,000 making it the fourth largest university in the UK. The University of Birmingham has consistently been ranked in the top four of the British Universities & Colleges Sport (BUCS) league table and was the first UK University to offer a sports degree in 1954.

Component Developments was approached to help design, manufacture and supply the stainless steel floor drainage solution for the University of Birmingham’s new sports facilities.

Component Developments designed the shower drainage channel solutions after multiple site visits to the University of Birmingham’s sports facilities, to ensure the channels were perfect for their application. The drainage channels designed used the 6010 drainage channel profile, which was specifically designed for leisure applications. This was topped with a Heelsafe grating, which has a smooth mesh making it safe for barefoot. Each drainage channel had a built in fall Component Developments 5150 gully which had the flow rate capacity to take the volume of water under shower cubicles, whilst also having a removable waste basket to help collect human debris such as hair which would otherwise cause a blockage; especially in a university with such a high volume of students.

Component Developments also supplied four different specifications of standalone gully, with bespoke welded spigots to match the site requirements to allow connection to the below ground drainage.

Each standalone gully pot was circular spun in order to help encourage waste to easily slide down into the waste pipe. This self-cleansing design helps to prevent a build-up on bacteria which is commonly found in the corners of a square boxed gully. The gullies also included a removable waste basket to collect any debris and prevent it causing failure, and a trap to prevent foul air being recirculated.

Component Developments also designed and manufactured multi-cover manhole covers. Due to the size of the manholes, it was decided it would be best as two removable covers with a central bar rather than one singular cover, to help make the weight manageable if the covers did need removing. All manhole covers were recessed to take the floor finish, double sealed, air tight and came with lifting keys.

Everything supplied to the University of Birmingham’s sports hall was manufactured in grade 316 stainless steel. This is because grade 316 unlike grade 304 has 2-4% molybdenum which increases its corrosion resistance properties, making it the better suited grade around places in contact with chloride such as a swimming pool, changing areas and showers.

The final overall solution supplied was a highly durable, sustainable floor drainage solution capable of withstanding the high traffic count due to the large amount of students that the University of Birminham has.