PcP Gratings Ltd

Suppliers of: Steel Scaffolding Planks, Metal scaffold planks, scaffolding planks, stair treads, mesh gratings, handrails

Scaffolding From PCP - With more than 35 years experience in designing and manufacturing scaffold planks, decks, toe plates and scaffold staircases. PcP is one of the leading manufacturers of scaffold planks within the European market.

By maintaining close contact with the industry, scaffold users and scaffold manufacturing company’s development of our products is carried out. This is undertaken using the latest 3D CAD/FEA systems and specialised testing facilities for full scale simulations.

PcP has a wide-ranging programme of standard scaffold planks, which can be used with most well known “System Scaffold” constructions.

Our planks conform with most other scaffold planks or decks. In addition, PcP will undertake to design “Bespoke” plank and platform systems to suit individual specifications.

Scaffolding From PCP.

With more than 35 years experience in designing and manufacturing scaffold planks, decks, toe plates and scaffold staircases. PcP is one of the leading manufacturers of scaffold planks within the European market.

Here are some of our product features:

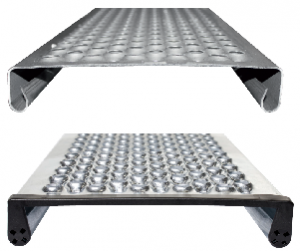

- Slip resistant surface

- Good drainage

- High strength to weight ratio

- Minimal maintenance

- Steel and Aluminium options

- Load classes 3-6

- Can be adapted to all systems

- Patented designs

- Approved according to EN 12811

- Single planks or as decks

- Extended life and durability

- Bespoke designs available

Further technical information is available to download from the BPi PDF Library.

Aluminium work platforms for industrial tipper trailers

Customised safety solution

One of the largest European manufacturers of tipper trailers used for bulk materials, chooses PcP as a partner to develop safe work platforms.

Optimal safety and high-quality combined with minimum waste

The project

The project was to provide an existing system with the new solution that offers high slip resistance according to evaluation group R13/V10* and to make it processable for a series production. For the new work platform on the trailers, a high-quality standard was to be achieved.

The task included strict criteria for using recyclable metal with a minimum of waste without compromising with quality. Furthermore, the platform solution needed to achieve a very high standard in terms of quality with an outstanding finish and dimensional accuracy. outstanding surface finish and dimensional accuracy.

The solution

Aluminium floors for tipper work platforms “From coil to finished product”

Optimal production technology in combination with high-performance materials enables production "from the coil to finished product" in terms of reproducible quality / extremely high dimensional accuracy / a perfect surface finish and economical production.

In cooperation with our customer and our suppliers in the field of material and surface protection, we have developed a solution that allows us to develop an aluminium floor for the working platform on our customer's tipper trailer, true to our motto of manufacturing "from the coil to finished product".

Due to our production technology of a sequence of several processing steps on a production line, we were able to develop a new floor for the working platform on our customer's tipper trailer using surface profiling (PcP Safety Grating Type US), we were able to achieve the slip-resistance classification required by the customer and certification by the Institute for Occupational Safety and Health (IFA in Sankt Augustin) - according to evaluation group R13/V10.

Furthermore, the tools and materials used have enabled the process accuracy and the processing speed to be optimized and improved to a large extent. In particular, the excellent cooperation with our material suppliers (special foils in order not to contaminate the tools with foil residues) enabled us to achieve a perfect surface finish as required by the customer. Further processing is therefore not necessary and minimizes operational ways and resources.

Quality assurance of products and series production

Due to the process-guided production, only the slightest deviations from the specified dimensional and quality requirements are possible. These are monitored and documented by instructed personnel and employees trained in the area of quality at specified inspection intervals. In particular, the product test bench set up for this purpose enables our employees to carry out a comprehensive test on the component and immediately correct deviations in series production.

The result

Custom made flooring meets the strictest safety criteria for tipper trailers

Due to the partly optimized tool technologies and adapted or partly new procedures and processes, the requirements of our customer's specifications could be fulfilled to 100%. The requirements of the employers' liability insurance association and occupational health and safety could be achieved with a certification (IFA) according to slip resistance class R13/V10. This decisive requirement was accompanied by the demands for process-optimized series production while meeting the requirements for dimensional accuracy and perfect surface finish.

As a result, we are confident that we can supply our customers with a product that lives up to their name and market position.

PcP unveils new brand identity& website to support international growth ambitions

PcP unveils new brand identity & website to support international growth ambitions

PcP unveils new brand identity & website to support international growth ambitions

September 23, 2020

PcP - one of the leading suppliers of gratings, treads, planks for safety solutions across industries announced today the launch of its new brand identity, reimagined logo, tagline and website. These changes come at a time where PcP's safety solutions and products are in high demand all over Europe.

"Our new brand identity under the tagline 'Engineering Safety' celebrates what we have always done and will continue to be committed to. Enabling our customers, no matter their industry, to safely operate in their daily business routines, surrounded by innovative PcP solutions", says John Nielsen, Group CEO and owner of PcP.

Through a brand-new user-friendly website, PcP merges their previous country-specific websites under a 'one-brand-one-website' vision. This promise ensures that existing and new partners meet the same identity and customer promise, no matter the market. "Our new brand identity is designed to emphasise our focus on safety and celebrate the innovative spirit that has been present in our company since its inception in 1927. The new brand identity supports our ambitions in further increasing the use of our safety solutions all across Europe".

Together with the relaunch, the company's well-known products have also been re-branded and grouped into three distinct product lines. These include the recently launched CUBE® product line - next generation gratings, planks and treads, with district aesthetics, excellent strength-to-weight ratio, superior slip-resistance and much more.

The new brand identity celebrates all levels of the organisation - from design and production to sales and marketing, through not only images of solutions, but the very people behind them. "High business ethics, innovation and diversity are values and virtues deeply embedded within our DNA. We owe those principles not only to our heritage but also to the people that represent our international organisation, who empower us to pioneer quality grating solutions".

Rather than a complete makeover, the new logo pays homage to the original PcP logo, leading the company into the new decade and beyond, with a modern, fresh and simplistic style. Designed to be recognised as a symbol of trust, the revitalised logo and core tagline evokes feelings of professionalism, safety and innovation. "Our new identity reflects the same approach we practice when doing business with our partners, looking to take safety to the next level".