FläktGroup - Boosting Air Quality & Energy Efficiency in Urban Buildings

FläktGroup - Boosting Air Quality & Energy Efficiency in Urban Buildings

FläktGroup - Boosting Air Quality & Energy Efficiency in Urban Buildings

FläktGroup – Boosting Air Quality

Ventilation is essential in keeping indoor air fresh. However, in airtight buildings designed to prevent heat loss and improve energy efficiency, natural ventilation is not an option. Here, Jibin Kurian, product manager at FläktGroup, discusses how the latest mechanical ventilation technology works to improve indoor air quality whilst minimising energy usage.

In the commercial sector, indoor air quality (IAQ) can affect the health, comfort, well-being and productivity of employees. Pollutants can be generated from a wide range of sources, including building maintenance and renovation activities, new furnishings or finishes, and building occupants.

However, the problem can be exacerbated in urban buildings because outdoor air pollution and noise discourages occupants from opening windows for ventilation. What’s more, in the winter, opening windows creates draughts which are a major source of heat loss and can make rooms feel uncomfortably chilly.

Maintaining good indoor air quality requires attention to the building's heating, ventilation and air conditioning (HVAC) system, as well as the design and layout of the space and pollutant source management. Fortunately, new mechanical ventilation technology is providing the opportunity for efficiency and air quality to be simultaneously achieved.

The challenge

Indoor air quality is not a simple, easily defined concept like leaky tap. It is a constantly changing interaction of complex factors that affect the types and levels of pollutants in indoor environments.

The challenge faced by specifiers working on buildings that are exposed to high levels of noise and outdoor pollution is to create an optimum microclimate to deliver a healthy environment that doesn’t compromise energy efficiency.

One proven efficient, and cost-effective, solution is the use of mechanical ventilation and heat recovery (MVHR) units. These work by extracting moist, stale air from the interior of the building and replacing it with fresh filtered air from outside. The system uses the heat from the outgoing air to warm the incoming air via an air-to-air heat exchanger mounted within the MVHR.

Highly efficient

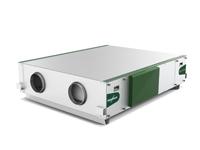

New technology works by recovering up to 85 per cent of the thermal energy thermal energy from outgoing air. Designed for buildings where space is tight, solutions such as FläktGroup’s eCO PREMIUM is available in different air-flow capacities and can fit into ceiling voids.

Efficiency is boosted by the way the system automatically adjusts to changing demands within a specific space, offering demand-controlled ventilation. With a presence detector, the system can switch on and off according to occupancy and an internal CO2 sensor adjusts the air supply in accordance with the number of occupants.

Importantly, the flow of outside air into the building helps to reduce the levels of allergens, as well as balancing moisture and humidity levels within the premises – all of which can vastly improve IAQ.

As an added benefit in noisy towns and cities, this type of mechanical ventilation can also limit outside distractions, with smaller openings in the façade compared to natural ventilation which is assumed to be fully open. The air handling unit themselves emit little noise – FlaktGroup’s eCO PREMIUM units for example, have low noise levels and are designed for applications where a quiet environment is essential, such as schools, recording studios and radio stations.

By deploying the latest heat recovery systems and demand control fans in mechanical ventilation units, designers can deliver ‘fresh’ air even where natural ventilation is not an option - and minimise energy usage in the process.